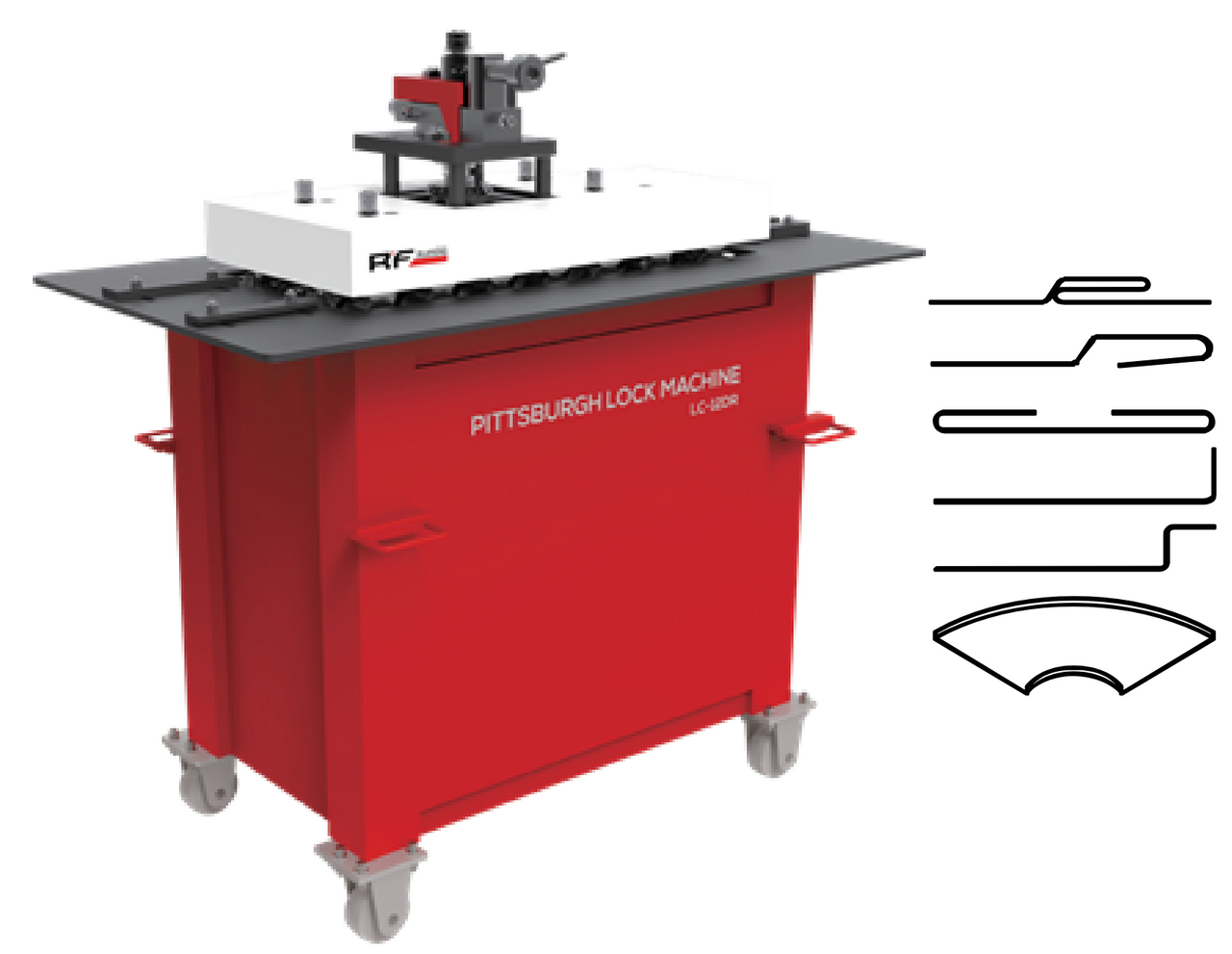

Pittsburgh Lock Former Machine LC-12DR

In the field of HVAC and ductwork fabrication, a lock former machine is often used for creating various types of locks, edges, and seams in sheet metal.

Here are some general features and capabilities that lock former machines may have:

Specification:

This 7-station lock former offers 6 forming positions, Pittsburgh and auxiliary double seam (ACME), right angle flange, drive cleat with slitter, as well as top mounted power flanger.

No adjustment for material 18-27ga (0.5-1.2mm)

√ Arc welded steel stand, heavy top plate

√ Roller material: GCr15

√ Roller shaft material: Thermal refined 45#

√ Transmission: V-belt

√ Control: Normal electric control

√ Speed: 26 FPM (9M/min)

- Lock Types:

- Pittsburgh Lock: A common type of lock used in ductwork that forms an inward fold on one side and an outward fold on the other, creating a strong and airtight joint.

- Snap Lock: Forms a standing seam that interlocks with another sheet, creating a secure connection.

- Versatility:

- Lock former machines are versatile and can be used to create various types of locks and edges to suit different fabrication requirements.

- Automated Operation:

- Some lock former machines are equipped with automation features, including programmable controls for precision and efficiency.

- Adjustable:

- Many machines offer adjustable settings to accommodate different sheet metal thicknesses and types.

- Material Compatibility:

- Lock former machines are typically designed to work with various sheet metal materials, including galvanized steel and aluminum.